PUMPA

PUMPA inox line VLTAVA stainless steel screw pump 3x400V

Czech product Stainless steel

from 412.47 €

Skip to content | Go to the main menu | Go to search

Don't have an account? Registration

A screw pump is a type of submersible pump that is suitable for pumping clean and slightly polluted water from boreholes and dug wells, or as a pump for a pressure sewerage. The pumps can fully supply a family house and are also suitable for irrigation and pumping into tanks. The pumps can be used alone or with a pressure tank and pressure switch as a pressure booster pumps with automatic operation. This solution will allow comfortable and maintenance-free use of your own water source.

To pump water from a depth of more than 8 m, we will use a submersible pump, which in the set with

forms a pressure booster pump.

When the pressure in the system drops below the set on pressure, the pressure switch automatically switches on the pump and turns it off when the set cut-off pressure is reached. In case of water shortage in the well and in case we have dry running protection installed, the switching device turns off the pump and protects it from damage. The dry-water protection switchgear will then not allow the pump to switch on until sufficient water level in the well has been reached.

Pumps for pressure sewers are used where it is necessary to overcome height differences and it is not possible to build a normal gravity sewer. They are ideal for lower sumps and pressure wastewater pumps with the appropriate conveying height are used. These pumps are installed in so-called pumping sumps, which are fully equipped small wastewater pumping stations. The sump is an ideal solution, especially for holiday homes such as summer houses and lodges, or even for permanently occupied properties if you have any problems connecting to the local sewerage system and obtaining the relevant permits.

The HD design has an improved grinder with excellent efficiency when cutting long solid particles. It is suitable for installations where there are problems, for example, with non-woven fabrics.

Drainage of sewage from the house can be realized by means of a pumping station(1) located outside the house. It is suitable for pumping and accumulating drainage and surface water, as well as wastewater from residential buildings and industrial plants. Pumping stations are made of polyethylene and can be provided with either one or two pumps(2). Reliable operation is then ensured by the control unit. When installing a pumping station, it is necessary to ensure its protection against the reverse flow of pumped fluid by means of a check valve with a ball (3). Due to possible service intervention, it is also necessary to install a shut-off valve on the delivery pipe (4).

1. Select the type of pump according to the size of the borehole

– we recommend a difference of min. 30 mm between the borehole wall and the pump

2. Find the required pump flow

The flow rate depends on the number of supply points and the number of people in the household. For a medium-sized family house with 3-5 people, we expect a nominal flow rate of 2 – 2.9 m3/hour = 33.3 – 48.3 l/min.

3. Find out the required head (conveying height)

The total head corresponds to the sum of 3 values:

For the medium house, a nominal flow rate of 2 m³/hour is suitable, so we choose with a reserve of 2.25 m³/hour.

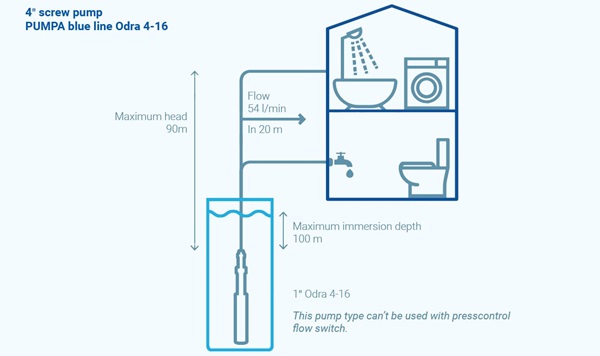

→ With the required delivery height of 70 m and a flow rate of 2.25 m³/h, the PUMPA blue line Odra pump comes out optimally.